Why This Flooring Solution Withstands Extreme Conditions

Industries operating in harsh environments need flooring that can endure the challenges these settings present. From chemical spills to heavy machinery, traditional floors often fall short. Robust and resilient, epoxy flooring stands out as a reliable choice. Its ability to resist wear and tear makes it ideal for maintaining a safe and functional workspace. This article explores why epoxy flooring is preferred for demanding industrial applications.

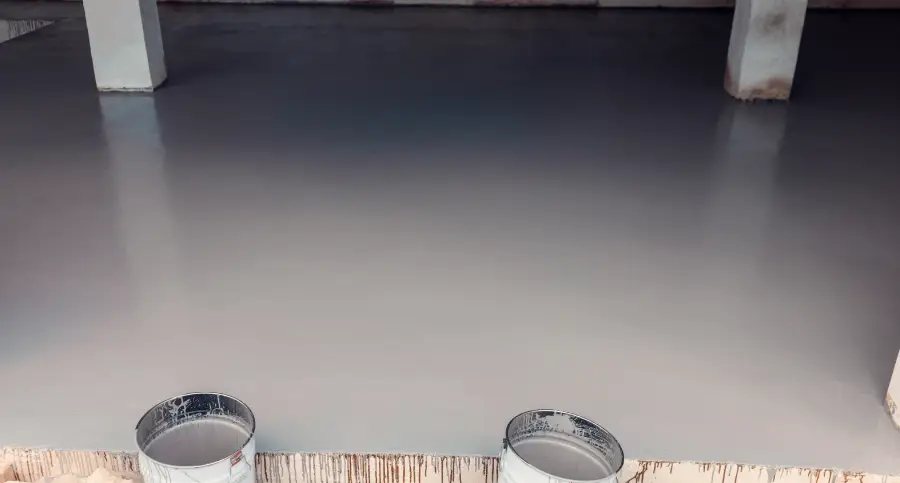

Understanding the Composition

Industrial epoxy flooring consists of a resin and hardener that form a durable plastic-like surface when mixed. This combination provides superior strength and resistance to various forms of damage. The solidified layer offers protection against chemicals, abrasions, and impacts, making it suitable for high-traffic areas. Moreover, its seamless nature prevents dirt accumulation, ensuring easy maintenance.

Benefits of Using This Flooring Type

Choosing this type of flooring brings multiple advantages to any industrial setting. It significantly reduces repair costs due to its long-lasting nature. Additionally, it enhances safety with its slip-resistant properties, reducing accident risks. Businesses appreciate its aesthetic appeal as well, since it can be customized with different colors and finishes. These features make it an attractive option for many facilities.

Common Challenges in Extreme Settings

Harsh environments impose unique challenges on building materials. Frequent temperature fluctuations, chemical exposure, and mechanical stress are prevalent issues. Many materials degrade quickly under such conditions, leading to frequent repairs or replacements. For businesses, this adds up to significant downtime and costs.

How Epoxy Solves These Issues

The composition of epoxy floors directly addresses these challenges. Their chemical resistance ensures longevity even when exposed to corrosive substances. The material’s ability to withstand varying temperatures without cracking makes it reliable throughout seasonal changes. Furthermore, its impact resistance handles the demands of heavy equipment operation smoothly.

Best Practices for Installation

Proper installation is crucial to maximizing the benefits of epoxy flooring. Here are some tips:

- Ensure the concrete base is clean and dry before starting application

- Mix the resin and hardener thoroughly to achieve even coverage

- Allow adequate curing time to avoid premature use and potential damage

- Consider professional installation for optimal results

Industry Standards and Compliance

Meeting industry standards is essential for maintaining quality and safety. Epoxy flooring must adhere to guidelines set by organizations like the American Society for Testing and Materials (ASTM). These ensure that floors meet specific durability and safety criteria. Compliance guarantees that flooring solutions not only perform well but also provide secure environments for workers.

Evaluating Costs and Benefits

While initial installation costs may seem high, epoxy flooring proves cost-effective over time. Its durability reduces the need for repairs and replacements, providing significant savings. The enhanced safety features also minimize incident-related expenses. By investing in quality flooring upfront, businesses enjoy a high return on investment.

Your Next Steps Towards Reliable Flooring Solutions

If your business operates in challenging environments, consider upgrading to durable epoxy flooring today. Located in Windsor, ON, our team at Allure Epoxy & Paint specializes in installing high-quality floors designed to withstand extreme conditions. Contact us at (226) 400-7074 for more information on how we can enhance the safety and efficiency of your workspace with our top-notch services.